SPONSORED CONTENT:

Leading cheese processors rely on optimized dicing and shredding solutions supplied by Urschel. Choose from the Affinity® Line of dicers or the CC Series of shredders. In the CC Series, the top two shredders are the CCX-D and the CC-DL. The CCX-D is the ultimate cheese shredder with Ra32 polished stainless steel and U.S.D.A., Dairy Division acceptance. The Model CC-DL is a version of the Model CC-D with a larger cutting enclosure.

Both the CCX-D and CC-DL feature the same operating principle. A rotating impeller located within a fixed cutting head employs centrifugal force to move cheese through the cutting head, actively cutting and uniformly reducing the cheese as product flows through the knife stations and exits the machine. Different styles of shreds may be generated depending on the style of offset knives. Available shapes include:

- Full & Reduced Flat-V® Shreds: Hexagonal cross section and flattened corrugated cross section.

- Full Shreds & Reduced V Shreds: Diamond cross section and ‘V’ cross section.

- Oval, Wide Oval, Reduced Oval (Crescent), and Wide Crescent Shreds: Oval-shaped cross section, wide oval-shaped cross section, crescent-shaped cross section, and wide crescent shaped cross section.

- Strip Cuts: rectangular cross section.

- Grating Options: Grating heads offer cuts including powders, coarse granules, and a variety of shreds depending on the head pattern.

The CCX-D and CC-DL both feature a larger 32” (813 mm) cutting enclosure which contains the cutting zone. The cutting zone is completely separate from the mechanical zone to promote sanitation. Available larger cutting chamber allows for greater alleviation of space surrounding the cutting head, and promotes positive discharge of product, while deterring product build-up.

The CCX-D is available with a 10 HP (7.5 kW) or maximum 15 HP (11.2 kW) stainless steel motor. The CC-DL is available with a 10 HP (7.5 kW) non-stainless motor.

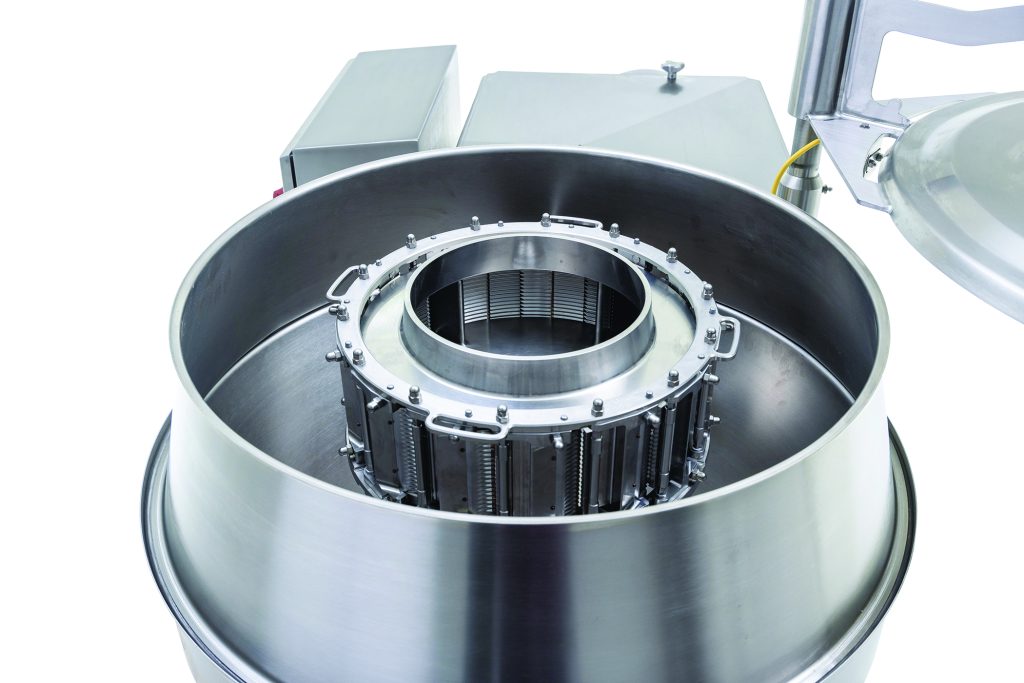

Urschel developed the MicroAdjustable® Shred Head (SH-14). U.S.D.A., Dairy Division accepted, the 14-station cutting head offers nearly double the capacity of the traditional 8-shoe shred head. The design incorporates ideal, carefully crafted spacing of cutting stations to maximize shred engagement.

The MicroAdjustable SH-14 shred head is available for use on the Model CCX-D in plants operating under U.S.D.A., Dairy Division guidelines. This head may also be utilized on other CC series models for shredding of products, including vegetables. Of note, both the CC-DL and CCX-D offer larger 32” (813 mm) cutting enclosures to work seamlessly with the SH-14 high-capacity shred heads.

The SH-14 delivers maximum cutting action with 14 cutting stations versus the fully-adjustable, standard head with 8 cutting stations — almost doubling the capacity. Quick-set shred thickness with a simple turn of engraved adjustment cams. Numerical values engraved on the top ring easily identify shred thickness. Angle wrench and block assist with knife changeovers and facilitate expedient assembly/disassembly for complete sanitation.

The SH-14 maintains strict tolerances throughout production runs with the ability to easily micro-adjust shreds using top/bottom adjustable cams by flexing the adjustable gate while the knife holder/knife edge remain in a fixed position. The MicroAdjustable SH-14 Shred Head fits in place of a standard double-ring, double-adjustment head using the self-locking lower ring, so there is no need for any special adapter. The SH-14 is lightweight at 35 lb (16 kg) and comes equipped with built-in handles to ease lifting.

Contact your local Urschel office to learn more about shredding with the SH-14 at www.urschel.com.