SPONSORED CONTENT:

At Reiser UK, we believe the key to developing and enhancing effective processing and packaging solutions lies in listening to the needs of food manufacturers. “This is how we tailor solutions to fit specific needs,” says Ed Hewitt of Reiser UK.

“We understand that each business has unique requirements and processes, whether they are producing one specific type of product or a broad range. Whether manufacturers know exactly what they need or require assistance in identifying the best solution, our expertise allows us to collaborate closely with them,” Hewitt continues.

Consumer demand for a wide variety of products in bakery

In the bakery sector, one of the key challenges is the sheer variety of products now demanded by consumers, which means that bakeries of all sizes are having to adapt rapidly to keep ahead of the trends to stay appealing and attractive to consumers. Labour shortages and the need to develop new products on a regular basis are common for businesses large and small.

So, equipment such as our Vemag HP1, which is adaptable for many products and can fulfil a number of tasks in either a small bakery environment or an NPD space in a larger bakery, is very appealing to many of our customers.

The compact machine can be used by smaller bakers as it has a smaller footprint than the larger Vemag machines and its quick-change attachments can be used for a variety of tasks. For larger bakeries, adding a Vemag HP1 can benefit new product development (NPD) kitchens by allowing the smaller machine to trial and develop new product lines.

Efficiency and quality in sausage production

What matters most to sausage manufacturers of all sizes is that their process is repeatable and produces the quality of product that their retailers and customers expect. When it comes to high volume production, the quality of a sausage product is largely determined by the efficiency and flexibility of the machines they are produced on.

Whether it’s pork, poultry or even plant-based, Reiser UK’s range of sausage linking machinery is tailored to the specific needs of processors, with careful considerations given to the scale and overall size of production.

Our Seydelmann range of bowl cutters, mixers, and grinders are suited to all parts of the industry regardless of scale, from a single machine solution to a production line for higher volume. Our machines are designed for gentle handling of the product, and the range is perfect for those looking to reduce size through cutting, whilst also maintaining high product volumes.

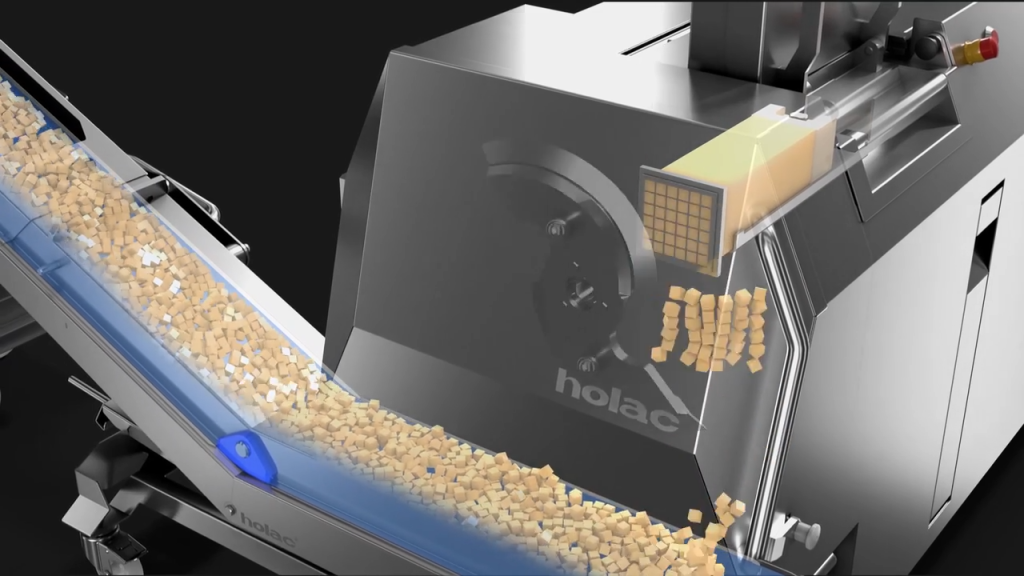

Cheese – overcoming downtime and waste challenges in production

The dairy industry faces significant challenges, particularly in cheese production, where handling a single product that needs to be grated, diced, sliced, or portioned can lead to downtime and waste. Manufacturers require efficient solutions that minimise these inefficiencies, reduce human error, and improve product consistency.

Reiser’s Holac range helps customers reduce waste, increase efficiency, and maximise production uptime, whether for grated, diced, or processed cheese.

Seafood – delicate handling

Seafood manufacturers require solutions to efficiently handle delicate seafood products such as fish fillets, shellfish, and other forms of seafood. Reiser excels at precise portioning and slicing of fresh fish, making it an ideal solution for both large- and small-scale manufacturing operations.

Our Vemag Multi-Screw technology is designed to efficiently handle delicate seafood products. Its gentle, high-precision operation ensures that the product is moved without damage, maintaining its texture and quality. It helps streamline the transfer process, reducing waste, and increasing overall production efficiency. This allows manufacturers to maintain consistent quality while handling high volumes of delicate products, meeting the industry’s demand for both efficiency and quality control.

Pet food precision and consistency

As the pet food market continues to grow, balancing quality, consistency, and efficiency has become crucial for manufacturers.

Our complete range of machinery helps in the preparation, portioning, and packaging of a wide range of pet food products, from dry kibble to wet foods, with high precision and minimal waste. It helps manufacturers meet the increasing demand for consistent portion sizes while maintaining the integrity of the product, particularly in delicate or semi-moist formulations.

Comprehensive packaging solutions

Packaging plays a critical role in ensuring freshness, functionality, and appeal. It is especially important in an era of fierce shelf competition.

“We understand that manufacturers need to make a strong first impression,” Hewitt notes. “Our Variovac thermoforming technology offers efficiency and innovation, helping food producers stand out. Focused on sustainability, our packaging solutions are versatile as they can be used with a wide variety of packaging materials.

“Supervac’s automatic vacuum chamber packaging machines deliver precision and efficiency for sealing products, providing a streamlined production flow, labour reduction, and a higher output.”

Driving innovation in food production

At Reiser UK, innovation is at the heart of what we do. “We are committed to supporting NPD (New Product Development) by bringing bold flavours, fresh ideas, and unique solutions to life,” says Hewitt. “Our approach is all about collaboration and understanding the specific needs of our customers.”

To further support this, Reiser UK’s purpose-built Customer Centre in Milton Keynes is a state-of-the-art facility designed to assist customers in product development and process improvements. “We offer hands-on equipment demonstrations and can tailor solutions for your unique requirements,” Hewitt explains.

“It’s where we innovate, experiment, and refine customers’ products and processes,” he adds. “Investing time here ensures product optimisation.”

Join us at a key industry event

Reiser UK’s commitment to providing innovative solutions will be showcased at Foodex Manufacturing Solutions from 7th to 9th April at the NEC in Birmingham, at stand Q110, hall 6.

To see our full range of machinery and services, visit our website. Or, to arrange a product trial at our Milton Keynes customer centre, get in touch with us:

Web: reiseruk.co.uk

Email: salesuk@reiser.com

Tel: +44 (0)1908 585300