SPONSORED CONTENT:

Converting to all food-grade lubricants reduces contamination risk, as the experts at Klüber Lubrication explain.

Look inside the lubricant cabinet of a food, beverage or pharmaceutical plant and it’s surprising what you might find. Upon close inspection, you might find a mixture of food-grade (NSF H1) lubricants and non-food-grade lubricants such as cleaners, glue removers and penetrating sprays.

When this happens and non-food-grade lubricants clutter up a storage cabinet, there’s always the chance that someone reaches for the wrong lubricant at the wrong time and the potential risk of an unexpected ingredient making its way into the product.

Given this possibility for end-product contamination it makes sense if the whole manufacturing site is food-grade, thus lowering any chance of contamination; even if mixing occurs the risk is mitigated.

Lubricants suitable for food, beverage and pharmaceutical applications are registered as H1 by NSF International (National Sanitation Foundation), an independent registration body, and comply with food regulations. These lubricants are physiologically inert, tasteless and odourless, and are suitable for incidental, technically unavoidable contact with a food product up to 10ppm. They can safely be used on machinery components such as pumps, mixers, gearboxes, chain drives and conveyor belts used for handling, canning, bottling, blending, chilling, cooking, cutting, slicing, and peeling.

Above the line versus below the line

The thinking used to be that you only needed to use food-grade lubricants ‘above the line’ and that industrial (NSF H2) lubricants could be used ‘below the line’, the idea being that components operating below the line presented no risk of contamination therefore using a non-food-grade lubricant was acceptable. This thinking has since changed as studies and experience have shown that contamination can occur from ‘below the line’.

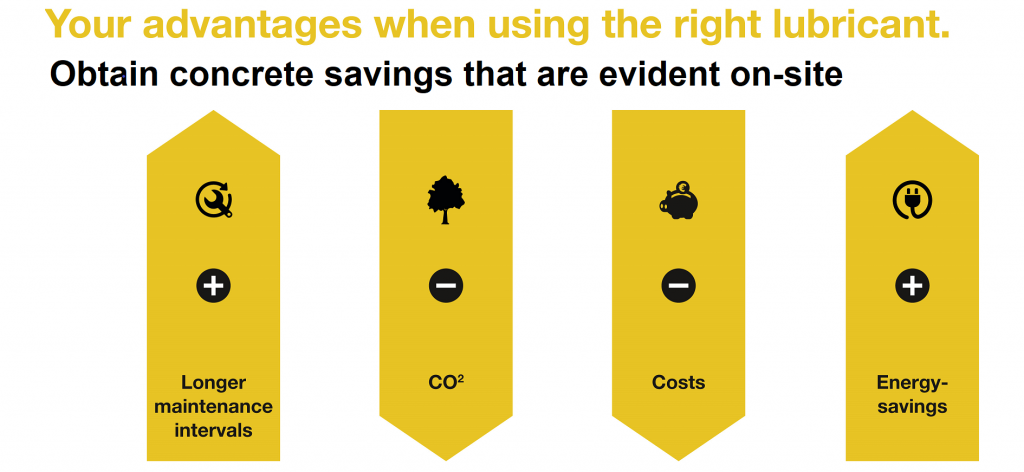

The only way to completely avoid contamination is to eliminate all non-food-grade lubricants in the lube cabinet and across the plant, but there’s a misconception that food-grade lubricants compromise performance. The good news for maintenance managers is that the newest lubricants designed for use in food, beverage and pharmaceutical facilities can do the same as conventional industrial lubricants, but with the added benefit of being safe for the consumer.

Performance and safety

Technical advances in the industry show that H1 lubricants can deliver the same or indeed better performance than conventional industrial gear oils and can be used safely on machinery components. Even at higher temperatures and loads or in wash-down environments an appropriate NSF H1 lubricant will still reduce friction and wear, protect against corrosion, dissipate heat and have a sealing effect. For example, Klübersynth® UH1 6 Series is a noteworthy H1 lubricant that offers superior performance in terms of efficiency, operational reliability and extended life. Some gearbox manufacturers use this H1 product for their first fill even when the box is not necessarily intended for use in a food, beverage or pharmaceutical facility.

It’s true that not all food, beverage and pharmaceutical companies are required to use H1 lubricants. However, by performing a careful inventory and converting to a NSF H1 registered lubricant facility, maintenance managers can eliminate any chance of potential contamination with hazardous substances leading to product recall whilst still achieving the same – or in many cases, better – equipment performance.

It’s a win-win formula that not only saves money when it comes to contamination clean-up, but it also pays dividends by driving food safety and quality forward in the plant environment for years to come.

About the company

Klüber Lubrication is a manufacturer of speciality lubricants headquartered in Munich, Germany. With over 3,000 products manufactured in a clean and safe environment and in partnership with the BRCGS, Klüber Lubrication are committed to your food safety initiatives from the start.

For more information about food-grade lubricants and best practices, visit our Food Safe Website.

Tel: 01422 319161