SPONSORED CONTENT:

Reiser UK has been involved in several projects in Ireland’s pet food market in recent months. Richard Watson of Reiser says that reducing labour costs and improved efficiency were key concerns amongst manufacturers.

“The food industry in Ireland is absolutely thriving. The beef and dairy industries have always been strong; and so, it is no wonder that we’ve seen some interesting applications come out of its pet food processing sector in recent times,” explained Richard Watson, managing director of machinery and equipment supplier Reiser UK.

The Irish pet food industry is one of the fastest growing sectors in Europe. Trade association FEDIAF, which represents European pet food processors, has reported that €27.7 billion in sales of pet food products are recorded annually, and that the European market is expected to grow in value by around 5%.

Having a strong presence within the Irish food sector, Reiser has been involved in several projects in recent months within its pet food market. Richard confirmed that central to each of these projects has been increased interest by manufacturers in using automation to help ease some of their biggest pressures.

He said: “Like the meat processing sectors at the moment, there has been a real drive for automation. Manufacturers want solutions that deliver less product handling and more product earned direct to pack.”

This trend towards automating, Richard explained, is largely being driven by a prevalent need within the industry to reduce food waste, improve food security and reduce reliance on labour. In fact, Bord Bia’s latest Performance report highlights the cost of labour as one of the “key risks to competitiveness”; and so, it is no surprise that many manufacturers are looking to automation to reduce this cost burden.

“Manufacturers are realising that there are big savings to be made on labour – particularly in the current climate where the cost of current shortages is only expected to increase,” Richard explained. “What we’ve found is that, by automating, our customers tend to deliver quality, consistent products which reduce costs drastically.”

Though the machinery supplier’s recent work within the Irish sector has primarily focused on processing, forming and portioning applications, Richard underlined that Reiser is well placed to custom-fit full line solutions as required.

“What we’ve found is that, by automating, our customers tend to deliver quality, consistent products which reduce costs drastically.”

He said: “What I think is brilliant about Reiser as a company is that we’re in a position to develop our solutions around the product that the customer wants to achieve. We’re able to put in test systems quickly so that customers can better understand what works and what doesn’t.

“We’ve got a huge range of standard – what we would call ‘serial’ machines – available that have been tried and tested, that are factory-ready; and we can set them up to fit any need.”

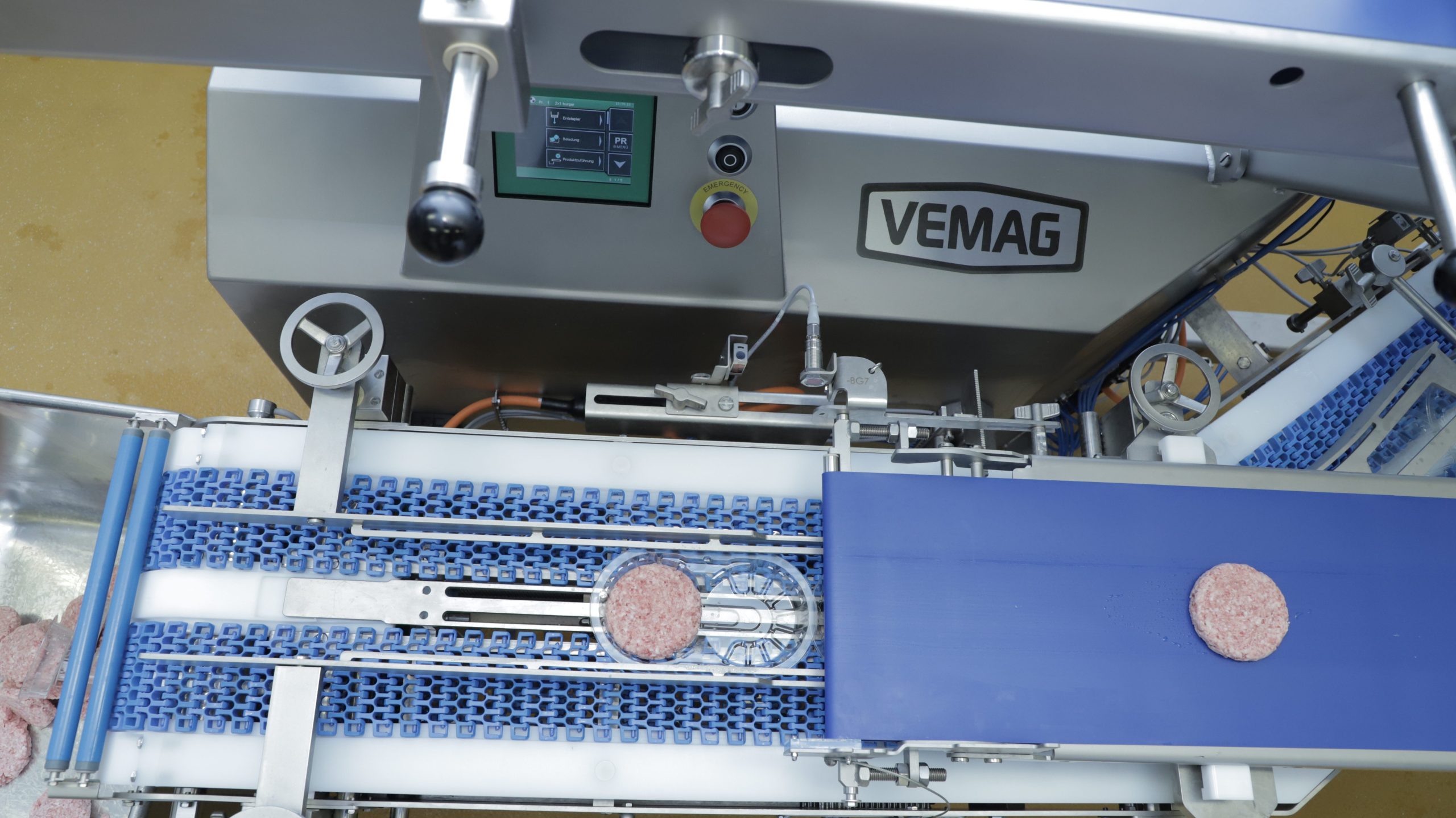

Amongst the range of robust, factory-ready equipment are machines from global brands including Vemag, Holac, Variovac, Supervac and Seydelmann; spanning a breadth of applications along the processing production line, from preparation and portioning to packaging.

A full list of Reiser’s machinery and services can be found here.

To organize a product trial at the Reiser UK customer centre in Milton Keynes, get in touch via the channels listed below:

- salesuk@reiser.com

- +44 (0)1908 585300