SPONSORED CONTENT:

GEA tells Food Management Today about the innovative products that are saving customers time and energy during slicing processes.

The packaging sector has always strived to make the best use of materials and innovative solutions. Now the focus has turned much more towards the impact on the environment, and carbon footprint is always at the forefront of any decisions being made. GEA has many slicing and packaging customers globally, encompassing the big multinational groups to the smaller family-owned factories, and has formed these relationships by always keeping the customer’s best interests at heart and providing them with the correct solution for their needs.

High performance slicers with reduced energy footprint

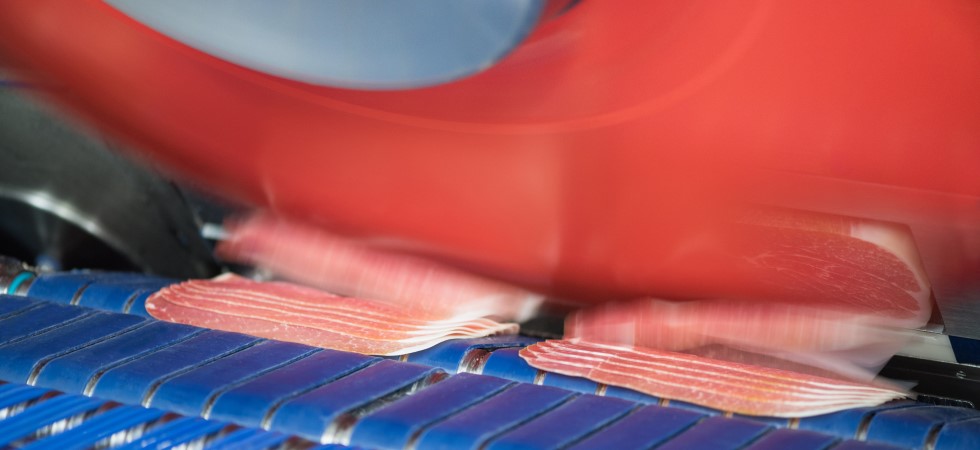

With its high-performance slicers that can be integrated into fully automated slicing and packaging lines, GEA is setting benchmarks for the global food processing industry. GEA engineers have now developed a special saw-tooth edge for involute blades that guarantees high-quality slicing without the need to first crust freeze products, such as cooked sausage and ham. By saving energy costs from the very first cut, this machine upgrade delivers a direct and sustainable improvement to the process’s energy footprint.

When it comes to sliced foods, manufacturers have clear expectations. To ensure high product yield, slice quality and output must be on target, and various factors impact slicing results. The two primary causes for variation in slicing results are technical aspects and the product itself. From a technical perspective, it’s the blade, the setup parameters and machine configuration that impact slicing results.

Product-related factors include the food’s consistency, the calibration and the temperature during slicing. The consistency of the food determines how the slicer is prepared for the slicing process. In addition to this setup, which includes, for instance, the pressure on the product and the log length, it is vital the product is at the optimum temperature.

Saw-tooth edge reduces cutting force

Thanks not only to advances in GEA slicing technology but also GEA’s purpose-designed blade, it is possible to slice without crust freezing. Slicing with a saw-tooth edge reduces the cutting force exerted on the product. The upshot is a “clean cut” given significantly less pressure is applied to the product in the slicing process. That means little or no crust freezing is required to form a crust on the product which prevents it from deforming during slicing. This results in savings in time and energy. At the same time, GEA’s new involute blades with saw-tooth edge reduce wastage and ensure a high proportion of on-weight portions.

Involute blade technology for high-speed slicing

Another benefit is that no retrofitting is required to take advantage of this slicing technology. All that is needed is to exchange the blade. GEA offers a range of involute blades in various sizes. They facilitate high slicing speeds of up to 1,500 revolutions per minute and support GEA’s idle-cut technology, which eliminates sliver slices. An involute blade is ideal for larger products because it slices through a larger log cross-section.

Norbert Brunnquell, Senior Product Manager Slicing & Loading at GEA, explained: “From a business perspective, the advantages are clear: The new blades eliminate the need to form a hard crust on the product using an expensive and energy consuming nitrogen crust freezing process. Likewise, they slice soft, fragile products accurately and precisely. Preparation time is shortened and the slicing process itself is simplified when crust freezing the product surface is taken out of the equation.”

Process optimisation

GEA’s saw-tooth blade is particularly suited for use with cooked sausage and hams which are optimally sliced at temperatures ranging from -1 to +2 degrees Celsius without crust freezing. Some of the technology group’s customers are already successfully using the new saw-tooth technology and benefiting from this sustainable process optimisation.

Norbert Brunnquell added: “We have customers of all sizes from those with a single machine through to national and global accounts with multiple sites and machines. Through working closely with all our customers, we can ensure we are in the best position to understand changing trends and requirements and react accordingly, with both efficiency and sustainability in mind at all times.”

Tel: 01925 812650

Email: FHT.UK@GEA.com